Supply Chain Logistics – Are we taking the right STEP (Strategy, Talent, Execution & Performance) to deliver and remain relevant in crisis?

The pandemic is on. Ever since it has set in, the world of logistics and supply chain got disrupted. And it is true for most of the businesses, setting aside a few which is purely local, having a short supply chain and simple in operations.

It would not be out of place to mention here a prophetic statement of famous management Guru Peter.F. Drucker which reads as follows: “The purpose of a Company is to create a customer … The only profit center is the Customer “.

Customer is the focal point. They are the lifeline of a business, of an organization and even to a supply chain logistics function of an organization. As we are aware that there are predominantly two ways to make a business organization running and thriving e.g., either by increasing the income i.e., revenue or by reducing the cost and alternatively may even be doing the both unless of course there is any disruptive innovation changing the course of the product, service and industry overnight.

Let us take the example of brick and mortar industries like steel and cement which although is in the core sector of the economy yet doesn’t have any palpable difference in terms of visibility i.e., branding, specs and offering. It is still making a transition from a commodity to a product and requires a clear-cut differentiator to create and maintain the sustainable competitive advantage. And Supply Chain logistics is one such discipline which not only for optimization of costs but for creating a better customer value plays an important role in delivering that much sought after sustainable competitive advantage.

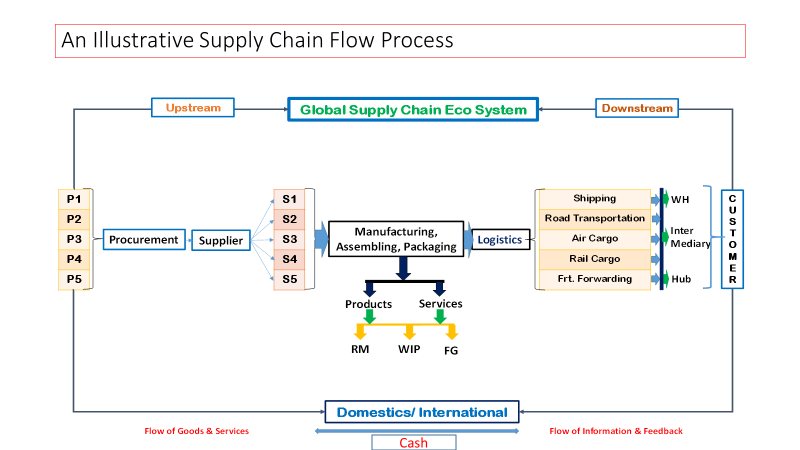

The exhibit 1 as given below illustrates a simple supply chain ecosystem. In order to further simply our understanding here we would use supply chain & logistics as one terminology although both are clearly and distinctively different where logistics caters to the physical movements (i.e., transportation) of goods and services to the end customers.

Exhibit 1

The major elements of the above supply chain logistics are basically supply i.e., raw material procurement, manufacturing and the logistics in terms of warehousing, freight & forwarding and delivery to end customers. But, there could be so many variants (models, options) which exists with respect to each of these elements e.g., warehousing say, distribution warehouses vs intermediary warehouses, freight forwarding in terms of rail, road, shipping, multimodal and delivery in terms of first mile, last mile, break bulk etc. There are various other important aspects of logistics like lead distance and time, order execution time, order delivery time, turnaround time (TAT), fill rate etc. many service level deliverables which clearly differentiates the agility and resilience of a supply chain within an organization. The primary objective of supply chain logistics as reiterated earlier is twofold e.g., value creation and cost reduction to contribute to the organizations’ bottom line and hence costs like warehousing costs, inventory carrying costs, transportation costs etc. also becomes a major driver of competitiveness and sustainability.

Now before delving further deep in to the holistic logistics solutions to drive competitiveness within the industry let us understand the nature and the challenges of commodities (transcending in to products) like cement and steel. Cement is high volume less value product whereas steel is high volume and high value product compared to cement although in logistics parlance both falls under the bulk heavy cargo category where transportation and handling often makes a distinctive difference in terms of customer serviceability and experience. Both these products are characteristically logistics driven since often the plants are set up closer to the market and since the customers do not want to commute beyond their locality to fetch the items. This is a very important aspect to be remembered while designing and developing an effective and holistic supply chain logistics strategy of an organization which is key to both survival and sustenance. Now if we talk about the challenges, the major ones are in terms of logistics infrastructure (both warehousing & transportation) and delivery since cement is prone to warehouse shelf life deterioration and steel is also prone to rusting. It also requires some customization in terms of cutting and bending and coiling before it is finally sold and delivered to the end customer.

We’ve also seen the vulnerabilities in the supply chain logistics during this pandemic. It is really unprecedented since it has impacted both the supply side as well as the demand side of the economy. To be more specific about logistics, it has impacted the warehousing and inventory management in terms of demand variability, transportation bottlenecks in terms of drivers’ and truck availability and supply side bottlenecks of product availability in terms of reduced or closing down of manufacturing operation due to social distancing, fear and uncertainty. One can not however take a solace to it that this is due to Covid 19, this pandemic. The social distancing is expected to remain and we are required to adapt to the changing environment and strategize to make our logistics supply chain more agile, resilient and customer centric. And it is not Covid alone but there could be any other similar crisis like financial or economic, natural disaster/calamity, like forest fires, earthquake, tsunami, geo political conflicts, geographical barrier like closed borders etc. which might also impede the efficiency & effectiveness of logistics supply chain at any given point of time. It is prudent therefore to embed the due risk assessment and mitigation plan in the organization’s logistics supply chain strategy to remain steadfast in its service, delivery and customer satisfaction.

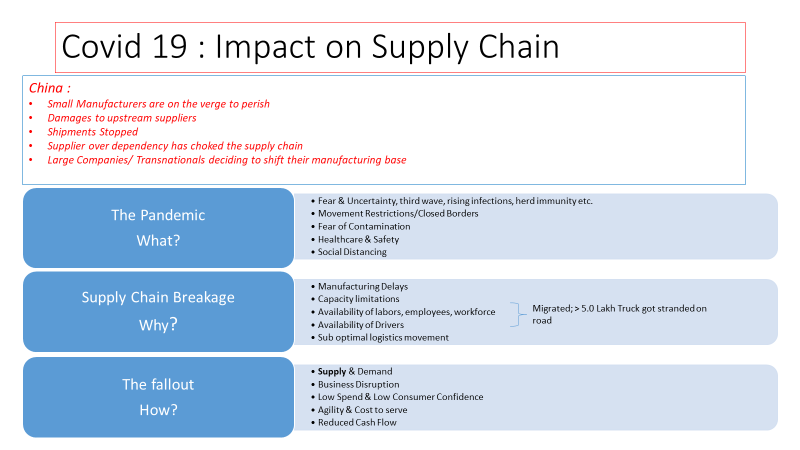

The exhibit 2 as given below describes the what, why and how impact of the current crisis which could be an eye opener for us going forward.

Exhibit 2

The traditional impact of any such crisis (major or minor) is mostly with respect to cost, time, safety, service level, company policy etc. which are intrinsic and factors like competition, government policy & regulation, trade policies, bilateral agreements, fuel cost, interest rates etc. which are extrinsic to the organization. As against this traditional impact the key impacts which a pandemic like this brings forth is massive disruptions in the supply chain logistics which either makes it unresponsive or may bring it to a screeching halt and also increases demand and supply variability across the supply chain as we move further from customer to supplier which is known as bullwhip effects. Now both these intrinsic and extrinsic factors hold good for steel and cement and one such glaring example is that during this pandemic steel exports to China has gone up as the Chinese manufacturing of steel got impacted. The cement in turn is mostly domestic demand driven and witnessed a greater variability during the current crisis and also the logistics impact in transportation due to lock down, fear & uncertainty, social distancing, healthcare & safety.

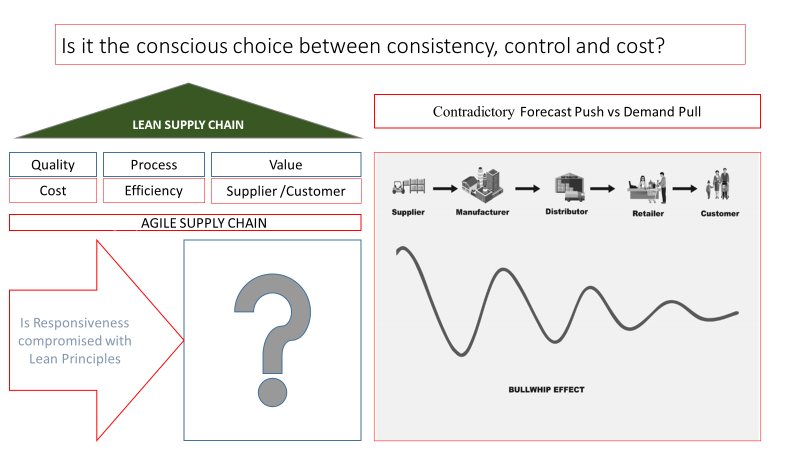

In light of the above once we look at the holistic solutions to drive competitiveness within the industry like steel and cement, we are required to make a conscious choice between consistency, control and cost. Often it happens that in order to remain cost effective, competitive and value driven we adopt lean logistics practices to focus on quality, process and on customer value but in turn sacrifices our logistics agility. Hence our strategy should be to remain agile and do not compromise the responsiveness with respect to lean principles. Apart while it comes to addressing a greater and larger variability in terms of inventory management (bull whip effect) the strategy should focus on how to improve upon our demand forecasting to reduce such variability in inventories across the supply chain logistics cycle as we move further away from customer towards the supplier. The exhibit 3 clearly illustrates the concepts as we’ve explained above.

Exhibit 3

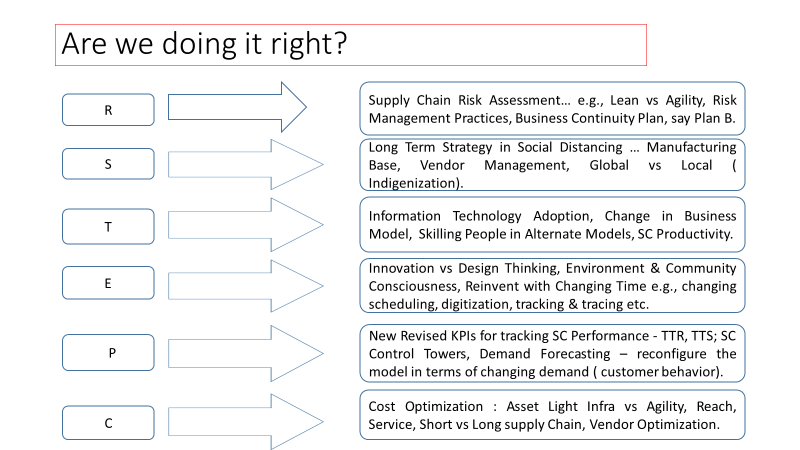

Now with respect to building our holistic logistics strategies we need to ask ourselves the question are we doing it right? The moot point here is to internally ask have we taken the right STEP (Strategy, Talent, Execution & Performance) as yet to mitigate the risk (R) and optimize the cost (C) which is the basic objective of any supply chain logistics strategy objective. Please see the exhibit 4 which clearly states what needs to be done with respect to the four pillars of strategy, talent i.e., people who could ultimately deliver the strategy, execution and thus leading to performance (measurement) of the supply chain logistics of an organization.

Exhibit 4

Finally, in order to remain relevant, competitive and responsive, any supply chain logistics should adopt either, or/and of the following e.g., (1) track & monitor changes in consumer /customer demand as that would drive constituting the primary strategy as to how do we respond to all our stakeholders in the logistics chain? (2) second we should explore reducing the supply across the chain to positively disrupt the supply chain and / or say, revisit our logistics footprint, shorten it (3) also mull over the option of moving from a complex to simple supply logistics chain, to be precise from global to local supply chain (4) strategically decide supplier switching in order to reduce supplier over dependency ( if, any) and finally (5) to go all out for technology adoption and digitization. All these would facilitate the flow of information back from end customer to the ultimate supplier, manufacturer including the supply logistics support service providers in an industry like steel and cement and thus help building the new age supply logistics chain to align, converge and compete in a VUCA (volatility, uncertainty, complexity, ambiguity) environment. A game changer in terms of leveraging our own resources and converting it in to promising future opportunities indeed.