The Corporate World is replete with examples of many a large that have gone into oblivion like Xerox, Nokia, Kodak, Motorola, Blockbuster, Blackberry Motion, Sears etc. What made them obsolete is change in technology, innovation and digital disruption. These were all iconic brands of their time gave way to indifference to embrace change. If we dig deep in to these companies (those who missed the bus) for example, say Kodak the pioneer in the photographic film market, was so engrossed in film marketing success that despite them inventing the first digital camera it ignored the digital revolution happened through photography and instead remained focused on film market apprehending of losing it and ultimately had to file for bankruptcy. Another example could be Nokia, despite being the global leader in mobile phones (20-25 years ago) at one point of time the company ignored the software development part of the technology, that not only the voice but data, messages, photo and videos also could be sent through mobile phones leading the advent of Smart phones which Nokia ignored and kept focusing on the hardware technology alone. There are other examples of Xerox losing out by focusing on copying business alone ignoring the opportunity in digital communication which eventually is replacing paper or say about Blockbuster, the largest video rental company having large stores all across US unable to foresee the Netflix’s rising in terms of on line streaming and eventually lost out.

Contrary to this if we see the most successful companies of say 2019 the names go like Google, Amazon, Facebook, HP, Cisco, GE, MasterCard, Volkswagen, Starbucks and so on. What did they do differently that they are thriving and kicking alive? The answer is that they all have invested in research and development of technology, keeping a close track of customers/consumers’ needs and behaviors, are open to experiment new opportunity, adapting to change by offering disruptive solutions with agility and not risk averse. The companies like Amazon, Facebook, Google, Cisco all of them are in fact pioneers in all the aspects as mentioned above and have created an ecosystem of idea generation, innovation platforms and fast enough adopt new technology always which has led them to reign the business and are phenomenal brands to reckon with. It is not the question of a big or small organization but the organization/s who could sense the opportunity and leverage it by becoming the first and prime mover.

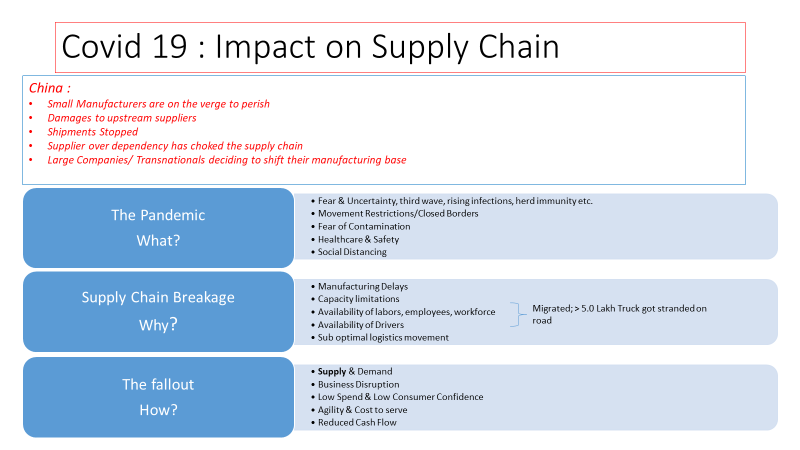

Let’s think of the unprecedented crisis and challenge we are facing now due to the advent of Corona virus (Covid 19) which has put almost all the economic activities to a screeching halt. There’s a fear for loss of lives, loss of business and even fear of unprecedented job cuts which may run in to several millions across the globe. The whole world is now waiting with bated breath as to when the much sought after Corona vaccine would see the day’s light, investing heavily in research and development, in medical and healthcare. Many a small disruption have started happening in terms of inventing small low cost ventilators, Covid 19 testing kits, e-health options like teleconferencing with doctors, further proliferation of e-commerce, e-logistics, e-learning platforms with new solutions and various other technological advancement for customer interface. The main objective is to have an increased technology and customer reach to stay alive and stay relevant now and even afterwards when social distancing perhaps may become the order of the day.

If we think it rationally, the challenge is the changing habits and behavior of people which is going to shape the future of our business. Unless the businesses are able to track such behavior changes of people, customers precisely we wouldn’t be able to come out with our new and improvised offerings in terms of products, services and solutions. It is said that our ability to see the behavior shits in people would be the key to success at this juncture. And technology has a big role to play in it e.g., starting with Covid 19 only, where Contact Tracing, a project pursued by both Google & Apple together to identify the people infected with Corona and track where are they moving. The objective is to provide protection to the community by making both the infected and the contacted individuals alert about it and advising them to go for medical help and/ or self-quarantined. Similarly google mobility data which is capturing mobility change of people by workplace, by retail and recreation and even by country during this pandemic is throwing us clear insight about how effective the lockdown is. This is really unprecedented in a sense that it is even able to monitor the closeness of contacts and the duration also with GPS & blue tooth technology. With such new technology tools we are now able to generate more information (data) and are using the data for public good. This is a combination of technological breakthrough coupled with innovation and creativity which has pivoted personal medical healthcare and safety of the humankind steering it to a new dimension.

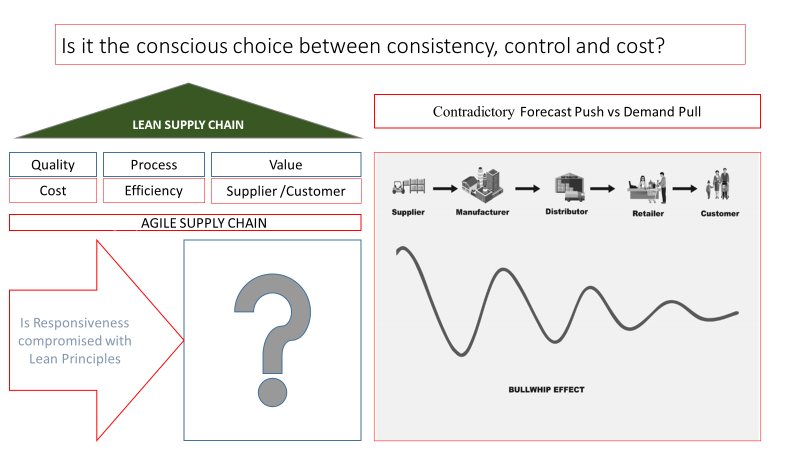

Now since peoples’ behavior and habits are changing we do not know how it is going to shape the demand for various goods and services in future. The demand sensing thus becomes an important task for any industry, businesses going forward because with low or no demand leading to loss of revenue, loss of business the organizations have started responding with job and or pay cuts. And internally within most of the organization the strategy is to preserve cash and reduce costs. Although preserving cash could be a short run strategy there’s nothing better than income generation which would be a long run strategy. And how do we reduce costs, may be by embracing more and more technology and automation of the existing business processes which will ultimately going to impact employment, jobs at one hand but is going to make us efficient and competitive on the other. We’ve seen in the past how technology and innovation has led us to so many industrial revolutions including the Industry 4.0 which is the current day buzzword. The industry 4.0 as stated to be the latest and fourth industrial revolution which refers to transformative technology which has and is changing the course of the industry. It is basically a whole network of them like smart factories interconnected with intelligent machines, the internet of things (IoT), Big Data, Block chain, Artificial Intelligence and Machine Learning etc. which is revolutionizing both the industry and human evolution. Looking back at the industrial revolution so far, we see the first one in 1770 which has led to the introduction of hand to machines and firms to factories for the first time. This was followed by the second one 100 years later in 1870 when the usage of electricity, steam, water power etc. was making a modest beginning of automation and assembly lines in factories. Another 100 years later we had the third one (1970) when Computers, desktops etc. have come up to replace largely the routine, repetitive and time consuming jobs and thereby enabled us to rethink and reshaping our business model when the globalization was setting in. And then came the fourth one, as we call it as industry 4.0 which is a very recent origin and has revolutionized almost all the aspects of businesses like production/manufacturing, sales, supply chain and logistics, research and development, and many more. The manufacturing including production and the supply chain fields are one of the major beneficiaries of industry 4.0 initiatives so far as we mentioned above. Let us discuss these with a few and concrete examples say, predictive maintenance as implemented by the oil giant Royal Dutch Shell Plc. Shell’s predictive maintenance is driven by the Artificial Intelligence (AI) wherein the AI powered tools can precisely predict when maintenance is required for its compressors, valves and can even alert the station employees of various risks it is running. The tool can also anticipate and inform Shell about which of the vast numbers (around 3000) of oil drilling parts can go wrong, highlighting the need for replacements and their available places of storage across all Shell locations and can even trigger purchasing and shelving of such spare parts in advance and at one go. This has resulted in attaining robust efficiency in inventory management where the inventory analysis time got reduced drastically from 48 hours to 45 minutes and saved millions of dollars on account of reduced cost of moving and reallocating various inventory. Another example could be Amazon Fresh (whole foods) where by focusing on big data analytics they were able to understand the customers’ grocery buying behavior and how the suppliers are interacting with the grocers’. And subsequently with the help of these data driven logistics it has been able to create more value for customers in terms of product development, delivery and where to initiate the further changes etc.

Now coming from global to local our own Axis Bank the largest private sector Bank in India has implemented robotic automation processes and deep learning to better understand the customer behavior patterns to respond to them with clear value propositions like streamline the document processing, shorter response time, identifying events which may lead to their leaving (customer turnover) etc. and accordingly offer them with special and customized sales promotion scheme, say customer retention schemes. They are now also developing some chatbots to engage with the customers and to reduce their waiting time for service in their busy branches especially during peak hours. The field of supply chain and logistics all across industries are having innumerable examples of how AI and Big Data has pitched for performance whether it is drones making loading of cargo into ships in mid sea or an AI sensor at the warehouses are keeping a hawk’s eye on stacking heights and sending alerts when it is about to topple and injures warehouse employees thereby removing safety hazards. The use of bots for unloading, loading (from and to the shelves) and transporting in to the loading bay is also increasing and becoming popular. The overall inventory management in several industries have undergone radical changes with the advent of data analytics, machine learning and automation and contributed towards significant reduction in inventory carrying cost and lead time.

Also while we talk about generating revenue through customer reach, service, sales, branding and marketing there are umpteen example of organizations using various CRM (Customer Relationship Management) platforms to tactically ensure customer reach, sales pitch, promotion, delivery and closing the sales in terms of the targeted outcomes. These customer interface (whether external customers like consumers, influencers. opinion makers, channel partners and/or internal customers like front line sales and customer service team members, various departments, business partners etc.) in terms of application software like say, Salesforce.com provides to plan the customer journey (Planned Journey Cycle), also provides with the required on line data to initiate dialogue with the customers, reminds them about jobs to do during the visit, review the targeted milestone achievements status, checking the status of various hygiene level of requirements like in shop branding, stock at hand, updated sales, delivery and service requirements etc. The Asian Paints example is worth mentioning here, the company has made this digital integration of its channel network with the salesforce seamlessly. Today the company, it’s top management at the HQ and its salesforce can able to track and monitor the channel (dealer and retailer) performance in terms of their sale, % of target achievement, status of stock and sundry debtors, utilization of sales promotion scheme (if, any), service and delivery on real time basis. This is now replicated in many organizations cutting across the industry sectors. It would also be worth mentioning here that companies like Hindustan Unilever as learnt from them that they’ve mapped all their retail outlets in the country (those which are called Mama Papa shops and approximately 5.0 lakh in numbers) during this lockdown to have a better understanding of their buying pattern, stock movement, customer behavior, future demand etc. to effectively serve the grocer/ stationery shop ( i.e., the retailer) in terms of technology enabled tracking and monitoring of customer and consumer habits, optimism, adaptation in the changing circumstances to accurately forecast the demand, better management of inventory and also meeting the delivery and service level expectations with more value added and customized offering which otherwise would perhaps done physically.

Customer and technology are the cynosure of all our business activity and today’s emergent leadership calls for more focus on innovation, idea generation and more to come out with technology based solutions. It should strive to create an ecosystem/service oriented platform, to have more focus on basic internal functions & processes and also taking due ownership of digital skills development for it’s employees/team as that would really pave the way for leveraging the entire gamut of what industry 4.0 offers to us in terms of technological breakthrough and adoption.